TRAILER SUSPENSION

There are a number of choices for suspension on a trailer that are practical and enduring and while there are other options such as swing arms, coil and shock absorber style suspension available, the following are the most popular.

Leaf Springs

Leaf spring suspension has been around in one form or another since Roman times and steel leaves have been used since the 18th century. You might think that using leaf springs on your trailer is a bit old fashioned, believe me its not. The reason why is we still use them is because they are so darn good. They are relatively cheap to manufacture, long lasting, easy to repair or replace and depending on the spring setup, can carry huge loads while reducing stresses on the trailer chassis and axles.

Springs are built to an upper load limit and need to be matched to the total trailer and load weight. Too low a load rating and the springs will bottom out and quickly fail. Too heavy and the ride will be stiff and harsh causing stress to both the trailer and load.

Leaf springs are available in almost any combination from very light duty single leaf to behemoth 12 leaf plus monsters. Find a spring that matches your load rating and find one that has a reasonable camber that suits your axle position

Springs are normally available painted, but galvanized leaves and also proprietary corrosion coatings are also available. Just remember that leaf springs are designed to slide against each other and wear between the leaves is inevitable and unpreventable. Galvanized springs, due to the nature of the heat treatment process may be slightly weaker overall and may lose their camber quicker than painted springs.

Poorly galvanized springs are prone to cracking and failure, although rare. Spring bushes do wear out especially if the trailer is constantly loaded to its maximum but are easily replaced - replace the spring bolt and locknut when changing the bushes.

Beware when buying cheap springs, apart from the good chance of buying poor quality springs, the bush material may be equally poor quality plastic. These will wear out very quickly. Good spring bushes should be good quality high strength nylon or a self lubricating alloy.

If a spring needs replacing for whatever reason, both springs on the axle should be replaced.

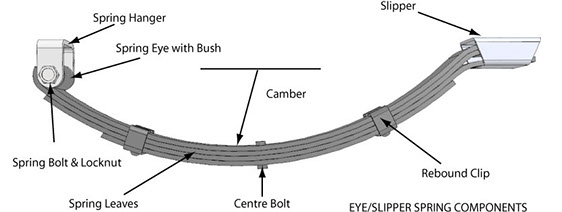

Eye/Slipper

This spring has the least moving parts of all springs although there can be a bit of wear where the spring tail rubs against its slipper. An anti rattle version is available as this spring can be very noisy over bumpy roads if the standard version is used. Using the slipper to retain the spring gives good lateral stability to the trailer and is especially good on a trailer with 2 or more axles because of this extra constraint. An advantage of these springs on a single axle is that the distance between the chassis and the spring is quite compact and can be helpful if you are after a lower deck height.

This spring has the least moving parts of all springs although there can be a bit of wear where the spring tail rubs against its slipper. An anti rattle version is available as this spring can be very noisy over bumpy roads if the standard version is used. Using the slipper to retain the spring gives good lateral stability to the trailer and is especially good on a trailer with 2 or more axles because of this extra constraint. An advantage of these springs on a single axle is that the distance between the chassis and the spring is quite compact and can be helpful if you are after a lower deck height.

Anti-rattle versions are available and are recommended. The third leaf is modified at the slipper end to fit snugly within the slipper thereby reducing any noise while traveling particularly when the trailer is empty.

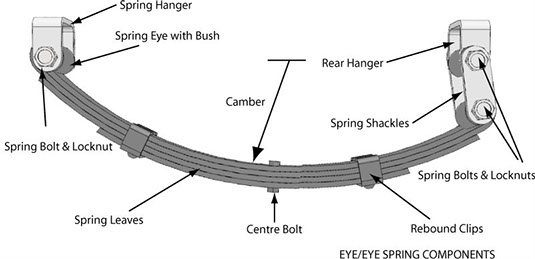

Eye/Eye

This is another common type of setup that rather than 2 loading points on the chassis with the slipper style, the dual eye has 3 distributed points which minimizes stress in the chassis and to some point to the axle.

This is another common type of setup that rather than 2 loading points on the chassis with the slipper style, the dual eye has 3 distributed points which minimizes stress in the chassis and to some point to the axle.

One end of the spring fits into a standard spring hanger and the trailing end hangs between a set of shackles which is mounted to the chassis. The spring requires correct set up to ensure correct operation. I have seen these springs tuck themselves in between the shackles and jam up due to very bumpy roads and overloading of the trailer. They are ideal for single axles but due not give as good side to side stability as the slipper style on a multi axle setup and reduces the axles load sharing capacity.

Another disadvantage is they take a bit more room up under the chassis and can limit how low the deck height can be.

Parabolic Springs

The Parabolic spring is the modern version of the leaf spring. It is normally a single leaf with a thicker center tapering out to the ends in a parabolic curve. The advantages of this spring is that there is no inter leaf friction, they weigh a little less than standard leaf springs and are not as stiff as leaf springs so gives a much smoother ride. Disadvantages are that they tend to take a lot of room up under the trailer so this can limit how low the deck height will be and the single leaf version has a lower load capacity compared to standard leaf springs.

The Parabolic spring is the modern version of the leaf spring. It is normally a single leaf with a thicker center tapering out to the ends in a parabolic curve. The advantages of this spring is that there is no inter leaf friction, they weigh a little less than standard leaf springs and are not as stiff as leaf springs so gives a much smoother ride. Disadvantages are that they tend to take a lot of room up under the trailer so this can limit how low the deck height will be and the single leaf version has a lower load capacity compared to standard leaf springs.

Multi parabolic springs are available and these are setup with spacers between each leaf to prevent contact due to the shape of the leaves. These will take more weight but again add more to the underside of the trailer raising the deck height considerably.

Torsion Suspension

Torsion suspension is basically a swing arm style axle which pivots within a rubber or elastomer enclosure.

Torsion suspension is basically a swing arm style axle which pivots within a rubber or elastomer enclosure.

As load is applied to the axle the torsion arm turns within the rubber causing the rubber to compress on one side and roll on the other and as the load is released the rubber moves the torsion arm back to its original position.

This type of suspension can give a very smooth ride as the trailer rides over the bumps with independent suspension. Another advantage is that the trailer deck height can be significantly lower to due the lower profile of the torsion unit.

There are a few disadvantages to this type of suspension as follows. Torsion suspension load capacity normally maxes out at 5500# (2500kg) towing capacity as a tandem setup, but due to the independent nature of the suspension and the way it is mounted on the trailer, axle load sharing is non-existent which can stress the chassis considerably. For this reason, when mounted on a tandem trailer, the axle rating should be reduced by around 25% to avoid bearing and suspension failure. For example over a bumpy road one axle will be working overtime while the other will be fully unloaded and this may cause the chassis to twist and stress cause rapid failure of your hubs and suspension.