Trailer Tongue Strengthening & Bracing

Bracing of the tongue adds vertical stiffness to the tongue section and should be used on trailers where the tongue length exceeds 5’ or 60” (1.5m) or where the tongue section has been built using undersize material, particularly on square section steel (SHS) or light wall section material.

There are plenty of variations, of which a couple are shown here, but the objective is the same and that is to add strength to the tongue without adding unnecessary weight.

The principle behind the brace is in effect similar to the truss arrangement of house roof supports and bridges - only upside down. The angular, vertical and horizontal components resist tension and compression (up and down motion) in the tongue as it goes about its normal duties.

Bracing is commonly retro fitted to older trailers where the original construction of the tongue was more of an afterthought than a planned exercise. Straight tongues benefit from the additional of a brace and it is common to see the “ladder style” bracing on these trailers.

Bracing is also recommended on heavy tilting tongue trailers to provide extra stiffness as the tongue is not effectively connected to the chassis.

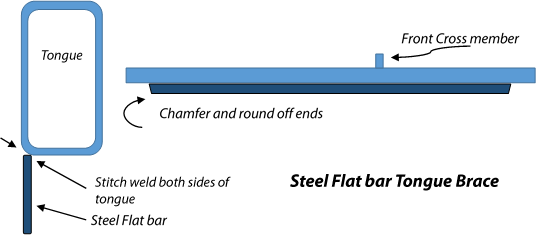

Because bracing normally sits below the tongue, it bears the brunt of everyday use, so it pays to make it as strong and as low profile as possible. Steel flat bar - 2" x 1/4" (50 x 6mm) or similar stitch welded vertically along the inside bottom edge of hollow section (RHS or SHS) works well if a low profile brace is required.

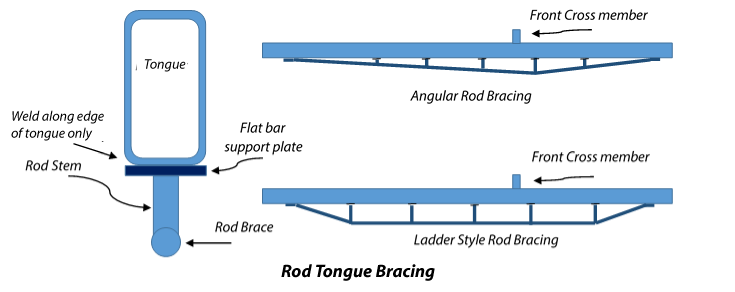

Rod bracing is popular and relatively quick and easy to fit. Tapering from the coupling end of the tongue down to 2-3" (50-75mm)deep past the first cross member and back up to the tongue underside with vertical stems at regular intervals gives excellent strength through the triangular form.

If using RHS or SHS material for the tongue - where the rod ends and stems are attached to the tongue, small pieces of steel flat bar should be welded across the tongue between the rod and tongue to prevent the rod and hollow section fatiguing from the up and down motion of the brace during operation. Weld these flats only on the outside edges of the hollow section and not across the bottom (horizontal) face of the tongue. See picture below.

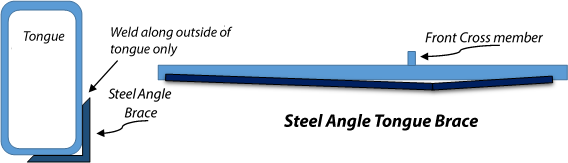

Steel angle can also used to create a sturdy, low profile brace and is stitch welded along the outside face of the tongue. The depth of the taper does not need to be too deep and can be around 2” (50mm) from the base of the tongue. Stems are not normally required.

If you want a strong, one piece tongue, you could get your local engineering shop to press a "C" section tongue out of 3/16" (4.5mm) or heavier, steel plate with an angular bottom profile similar to the photo below. This does away with any exterior bracing and should handle just about anything that can be thrown at it.