Are you constantly scraping the back end of your trailer exiting the gas station, or wanting to do some back country camping but are concerned about losing your trailer undercarriage on the rough roads? Is your trailer sitting bum down, nose up and you have tried all the standard methods of levelling your trailer?

It might be time you considered “flipping” your trailer axles, a relatively easy method to alter the level of your trailer and a great way to increase the height of your trailer above the road.

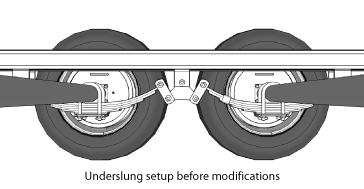

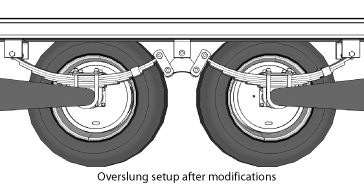

Trailers are inherently almost always designed and built with the axles “underslung” where the springs are positioned under the axles. This setup provides the trailer with a lower center of gravity, improves the trailers stability on the road and helps prevents trailer sway. Underslung trailers, being lower to the ground, also have a better aerodynamic profile when travelling and this helps reduce drag and improves fuel economy.

Flipping the trailers axles to sit below the springs, or “overslung” will increase the trailer body height above the road up to 6” and should give you plenty of clearance to take on the back country roads or the dodgiest gas station curb.

Raising the trailer will raise the trailers center of gravity and can potentially make it more sensitive to cross winds and trailer sway. If your trailer travels securely on the road at all times, flipping the axles will not be a cause for concern. If your trailer is sensitive to sway or has stability issues even on a good day, flipping the axles may not be such a good idea until the root cause of your instability has been remedied.

If the trailer is not towing level behind your vehicle and all other methods of lowering the front end of the trailer have failed to provide an adequate solution, “flipping” the axles could be the perfect solution.

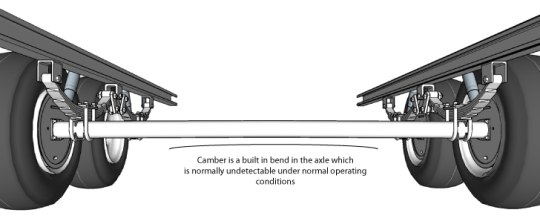

A note about the term “flipping” – the axles on your trailer come with a pre-existing camber (a vertical upward kink/bend in the axle center). This is to allow the axle to flex with the weight of the trailer and its contents, and run with the tires square and true to the road. Without camber, the weight of the trailer would force the tires to run unevenly on the road, causing premature tire wear, poor trailer tracking and damage to the running gear.

Flipping of the axle is not actually undertaken - the axle is kept in the exact same position and the components attached to the axle are raised above it.

Lifting the trailer may require an additional foot plate to be fitted to your access steps once the modifications are complete, and if your levelling jacks do not have enough travel for the increased trailer height, you will need to fit new longer jacks or carry hardwood chocks to compensate.

Parts will need to be ordered before embarking on the “flip”. Check your axle diameter and get an “over/under conversion kit” from your local or online parts supplier. The kit should include new spring perches, spring plates, and U bolts.

If your trailer has a few miles under its belt, this is probably a good time to order and fit new spring bushings and bolts at a minimum, and replace the spring equalizer, shackle plates and bolts while you are at it.

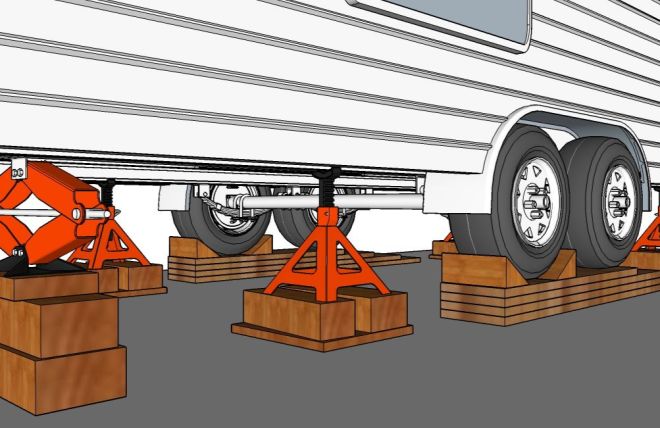

Get down to your local equipment rental center and pick up suitably rated jack stands, and trolley jacks to help get, and keep your trailer off the ground and in a safe, stable and secure working position.

Safety -

Safety is paramount when working under your trailer and no shortcuts should be taken. All work should be undertaken with the trailer fully supported by rated stands on solid ground with suitable hardwood chocks and cribbing to help spread and support the weight of the jacks and trailer.

Never use the trailer levelling jacks as the primary source of support. Always use jack stands in conjunction with the levelling jacks. Ideally, never work alone – always have someone or a means to get assistance if required, handy.

Raising the Trailer -

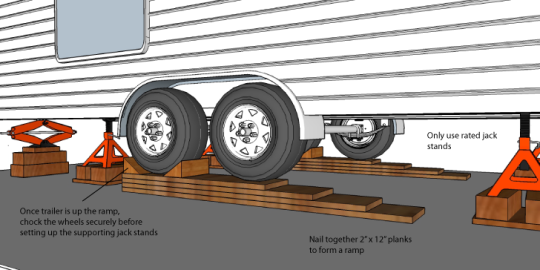

Getting the trailer sufficiently high enough that you can get the wheels back on after the modifications have been done requires raising the trailer at least 8”. The simplest method is to nail together 2” x 12” planks into a makeshift ramp as shown in the diagram below.

Get someone to guide you while you tow the trailer up the ramp. Chock the trailer wheels securely before unhitching or crawling under the trailer.

Once the trailer is secure, position the jack stands evenly under the trailer chassis, making sure that they will not crush or damage any cables or lines.

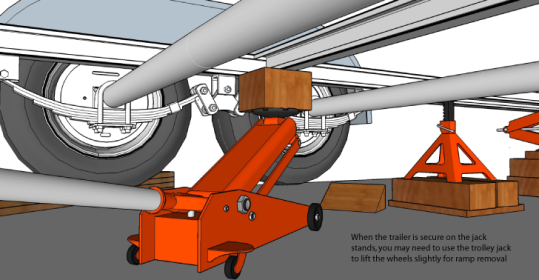

Use a trolley jack to lift the trailer at each point to get any additional height advantage from the jack stands. When the trailer is fully supported, remove the makeshift ramps – you may need to use the trolley jack to raise the wheels slightly off the ramp.

Do not use the trolley jack to lift the axle tubes, they can be easily damaged.

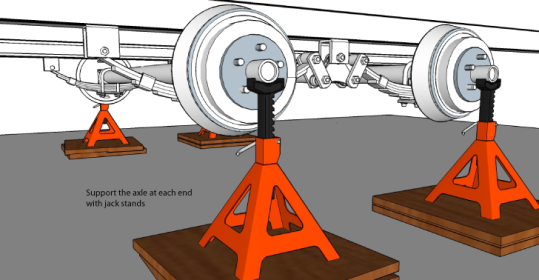

Remove the wheels and support the axles at either end with additional jack stands.

The brake wiring will normally need to be lengthened to allow for the height difference once the modifications are complete. Label the wires and disconnect or cut them allowing plenty of wire length for stripping and fitting crimp connectors for fitting the additional wiring when reinstalling the axles.

Working on one axle at a time, remove the shackle plate nuts, and tap the bolt and shackle plates off the equalizer and spring. Some manufacturers fit spring and shackle bolts with serrated shoulders to prevent the bolts from turning in the mounts. If this is the case, they may require a bit of force to knock them out of position.