Choosing, Installing, and Using Jockey Wheels and Stands:

Jockey wheels and stands are essential components for maneuvering and stabilizing trailers when not attached to their tow vehicle. Whether you're towing a boat, a caravan, or a utility trailer, selecting the right jockey wheel or stand and understanding how to properly fit and use them can greatly enhance your towing experience. In this guide, we will explore some of the key factors to consider when choosing this handy dandy trailer accessory, how to fit them, and best practices for their best life.

- Jockey wheels are designed to support the front end of a trailer and provide easy maneuverability when it is disconnected from the towing vehicle. Here are the primary factors to consider when selecting a jockey wheel:

a. Weight Rating: The weight rating of a jockey wheel should match or exceed the drawbar weight of your trailer. This will ensure that the jockey wheel doesn't fail while in storage or while manually moving the trailer unaided.

See the picture below, showing a jockey wheel mounted too high meaning the jockey wheel stem is at full extension and bending. The winder handle is also missing and makes for unsafe and uncomfortable winding.

b. Wheel Size and Material: have a think about the terrain and surface conditions where you will be unhitchingand storing your trailer. Larger wheels are suitable for rough ground, while pneumatic wheels provide smoother rolling, but, can go flat at the most inopportune moments.

Additionally, opt for wheels made from durable materials such as rubber or polyurethane for improved longevity. One the best allrounders is a solid rubber tyre on a nylon or pressed metal rim.

c. Swivel and Locking Mechanisms: A jockey wheel with a swivel mechanism allows for easy maneuvering in all directions. Ideally the swivel pin can be adjusted to take up any wear, (normally a nyloc nut). Look for one that also features a spring loaded locking mechanism to keep it securely in place once positioned.

There are models that have a quick release clamp for sliding the jockey wheel and support tube up away from the ground, as well as removing for storage in the trailer or tow vehicle.

Tip -when the trailer is hooked up to the tow vehicle, swivel the jockey wheel up so both the wheel and winder handle are positioned to the top of the drawbar. This protects both the wheel and handle from being damaged when going over kerbs or uneven ground.

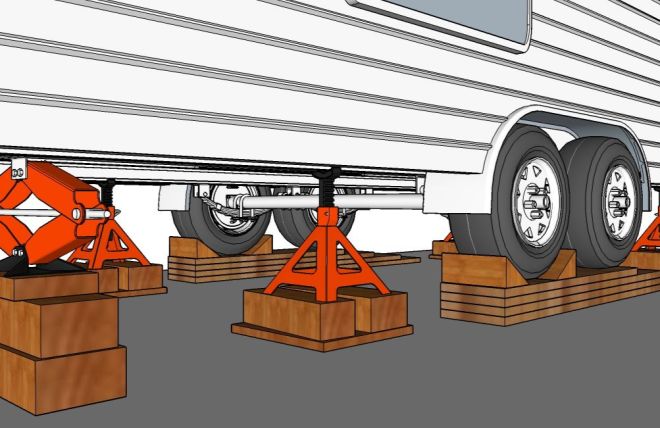

- Trailer stands, also known as machinery stands or stabiliser jacks, provide stability for a parked trailer. Trailer stands are more like the boof head brother of the stand world, strong, stable and dependable, but not much good for anything else, unlike their jockey wheel counterparts. They are normally rated for a higher drawbar weight but do not have the manouverability or the same storage capabilities as a jockey wheel.

a. Load Capacity: as per common sense, check that the trailer stand's load capacity is capable of supporting the weight of your trailer, including any added cargo.

b. Construction and Material: Look for stands made from durable materials such as steel or aluminum. They should be rust-resistant and able to withstand the elements.

c. Retractable vs. Static: Retractable stands offer the advantage of adjustable height and compact storage, while static stands provide a stable base without the need for adjustment, but with the added disadvantage of being more likely to connect with the ground at times.

- Fitting and Installation: Proper installation is vital for the effective functioning of jockey wheels and stands. If the stand has a swivel unit fitted, follow the instructions as per the jockey wheel below, otherwise, check and follow the manufacturers installation recommendations. If all else fails, read and follow the instructions that come with your jockey wheel or stand.

a. Swivel style Jockey Wheel Installation:

- Normally fitting a jockey wheel to an existing trailer entails either clamping the jockey wheel to the drawbar using “U” bolts or means drilling the drawbar to bolt the unit on.

- Fitting a jockey wheel with “U” bolts is pretty self explanatory and if this option is available to you, then this is the recommended way to go. It allows easy adjustment and replacement if required. The following is for the “drill the drawbar” brigade -

- Position the jockey wheel mounting pad on the side of the drawbar (if room allows, fitting the jockey wheel inside the A frame is recommended) keep the jockey wheel as close to the coupling as sensible, ensuring that when the jockey wheel is up and retracted, that it does not interfere with the coupling, chains and shackles or the tow vehicle when reversing tightly.

- Check the operation of the jockey wheel in its up and retracted position, while keeping the jockey wheel pivot point in the same position.

- Check the height of the jockey wheel mounting point allows the jockey wheel to be clear of the ground when swung around ready for winding the coupling off the tow vehicle.

- Mark the hole centres of the mounting pad with a marker, check the marks are level with the top of the drawbar and centre pop the marks ready for drilling.

- Pre drill the holes through the drawbar using a drill bit smaller than the finish3d bolt size diameter.

- Drill through with the correct bolt diameter drill and try to clear as much swarm away from the drilled area as possible. If you have access to compressed air and can clear the inside of the drawbar, blow it out now.

- Apply some rust preventer, primer and paint to the bare steel

- Place the jockey in position and fit the bolts, ideally with the nuts on the inside of the drawbar. Use spring or lock washers and bolt up securely.

- Check the operation of the jockey wheel, give it a grease up and you’re good to go!.