3.6 X 2.0m Flatdeck Trailer

Tailgate Fabrication

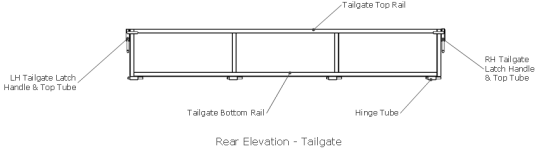

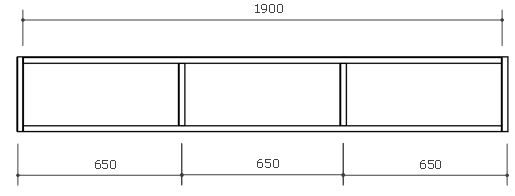

TAILGATE

Build the tailgate as you did with the sides (mitre corners if preferred).

NB - The height of the tailgate uprights is dependent on the deck material thickness. For a 17mm plywood deck as this trailer is shown, the end uprights measure 317mm high to allow for the deck.

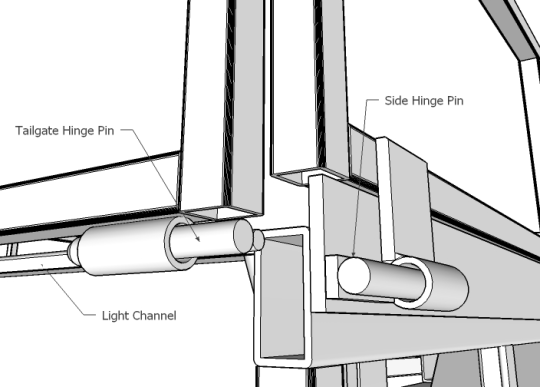

This ensures that the hinge pins mount correctly on the rear light channel

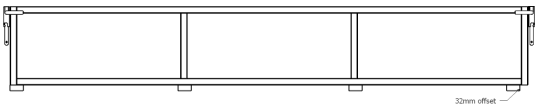

The hinge pipes are 15NB Medium pipe cut at 50mm long. Fit the left hand side flush with the end of the upright and the right hand side pipe 32mm offset from the end. Position the other 2 hinge pipes evenly along the bottom rail.

All hinge pipes need to be flush with the inside, vertical face of the bottom rail.

The latch top tube and packer plate can be welded into position, flush with the top of the upright with the slot facing the rear. (See Latch and packer details below)

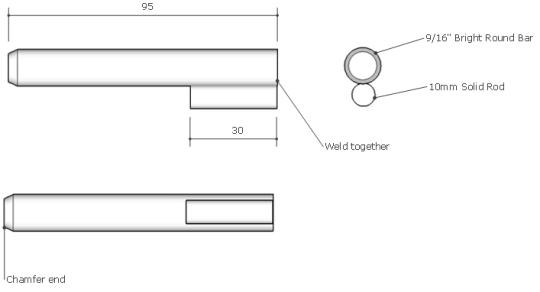

Make up four hinge pins for the tailgate using the details below.

FITTING SIDES AND TAILGATES

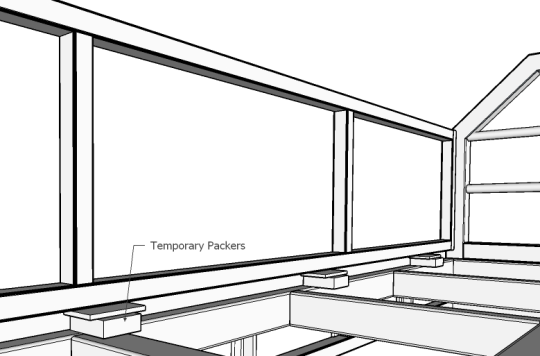

Cut some decking offcuts and short 5mm flatbar packers and set these along the outer chassis runner to give the correct height for the sides.

Position the sides on the deck and steel packers and line up the front upright with the headboard. Allow a clearance between the side and headboard of around 2-3mm.

Clamp into position on the antiluce latch plate and check along the length that the side is vertical and in line with the chassis side edge plate.

Position the hinge pins into the hinge pipes and level before tack welding. The hinges should be setup so that the side needs to slide forward to be removed.

Once all the hinges are tacked into position, gently open and close the side and check for any tightness or binding. Adjust where required to ensure a smooth open/closing action.

On the headboard, mark the centre of the latch plate and drill through and fit the antiluce latch. If welding the latch on, double check the latch orientation before welding.

Get a mate to help you lift and position the tailgate up to the offcuts and centrally between the sides. Clamp to the offcuts and once sure of the tailgate position, tack weld the hinge pins to the light channel.

As with the sides, unclamp and gently operate the tailgate, looking for any binding or stiffness.

Adjust the hinge pins as required to ensure a smooth open/close operation.

Check the latch positions and that they are functioning correctly. Re-position if needed.

Fully weld latch tubes and hinge pins on both tailgate and sides once you are happy with the setup.

Cladding of the sides is best done once the decking has been cut and laid in situ.