4'6" X 7' SINGLE AXLE TRAILER: FENDERS

To find the correct position of the fender, fit the axle to the springs loosely, dry assemble the bearings and hubs and fit the wheels to the hubs.

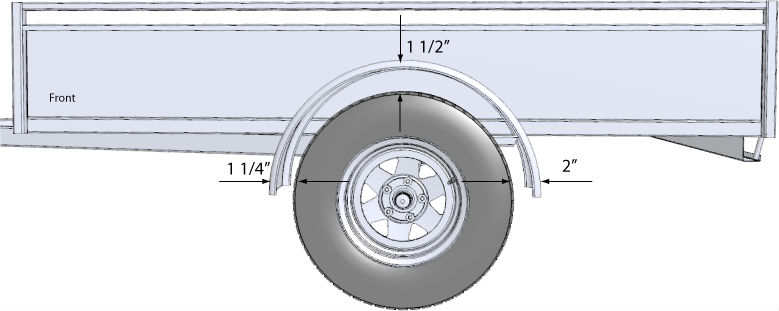

Place an off-cut of timber or steel around 1 1/2" thick on top of the tire and lower the fender onto this. Stand back and check the clearance around the front and rear. The fender can be pulled open if needed to allow for a better fit. Whatever measurement you pulled the fender out to, make sure that the other fender matches.

The fender needs to have roughly equal clearance at the front, top and rear, but pays to give a little extra at the top and rear to compensate for spring movement.

A good rule of thumb is 1 1/4" clearance at the front, 1 1/2"at the top and around 2" at the rear, or of similar ratios.

Once the fender is in the correct position, tack weld the fender in position (another set of hands is recommended. Make sure that the fender is in full contact with the panel side and then stand back and make sure that the fender is in the correct position.

If the fender doesn't look quite right, now is the time to adjust it.

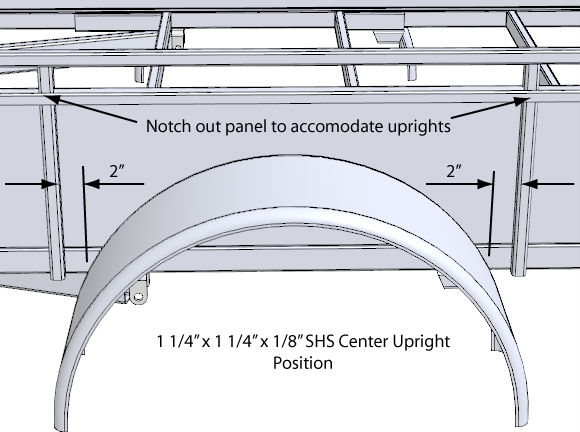

Mark out 2" from both front and rear of fender at the base of the chassis rail, and using a large square, mark up the panel to the top lip, measure 1 1/4" away from the guard and mark on the lip.

Using a grinder with a cutting blade, notch out the top lip back to the main panel to fit the center uprights.

Position uprights square with the chassis rail and tack weld into position.

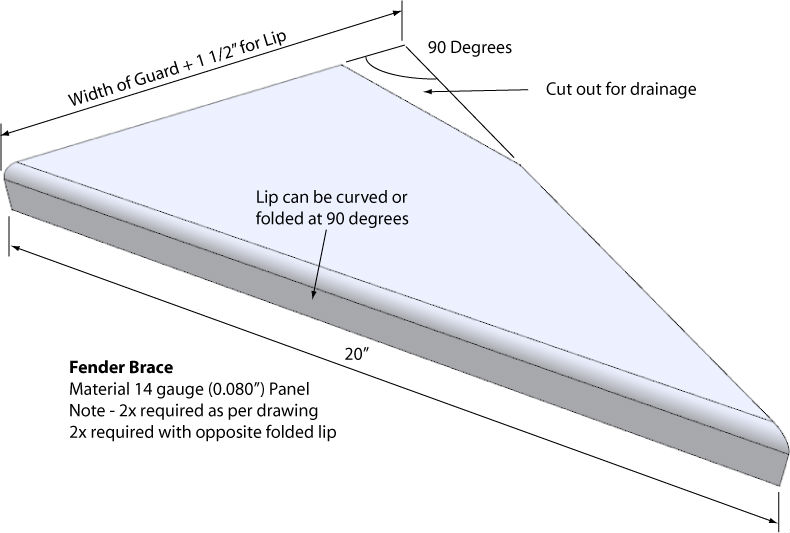

FENDER BRACES

Fender braces provide a couple of necessary functions, firstly to give the fender strength and support especially as the fenders are normally the first things to get knocked around. Secondly they function as a step onto and into the trailer. Be wary of using a piece of rod or pipe to brace the fender, slip on this, when you are climbing into the trailer, you are likely to break your leg if you fall between the brace and the trailer.

When fabricating the braces, ensure you make 2 pieces as per the drawing and 2 pieces with the lip folded the opposite direction. The drainage cut out is to help prevent debris and water settling causing corrosion.

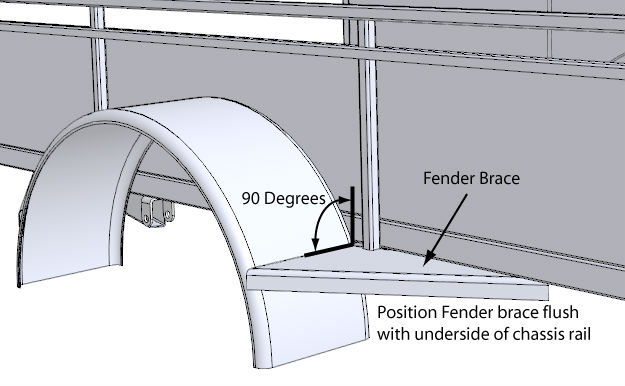

When fitting, make sure the brace is square with the side and flush with the underside of the chassis rail. This is another job where a spare pair of hands is useful. An out of square brace is very noticeable so take care getting it right.

Once everything is tack welded in position and looking right, stitch weld along the outside of the trailer along where the panel and chassis rail meet. A 2" stitch weld with a 4" gap is perfect. It is not necessary to weld the panel on the inside of the trailer.

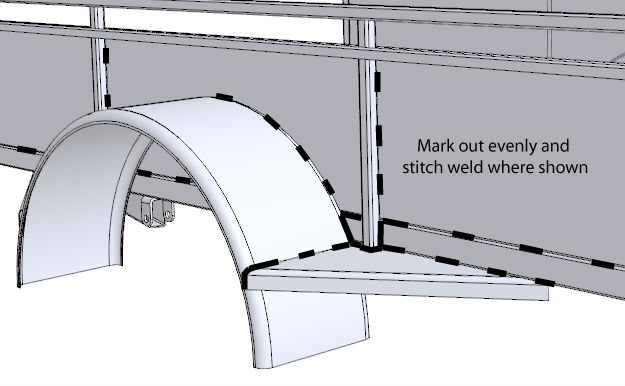

Stitch weld both sides of the center uprights, around the topside of the fenders and braces and fully weld all visible joins around the top portion of the center uprights.

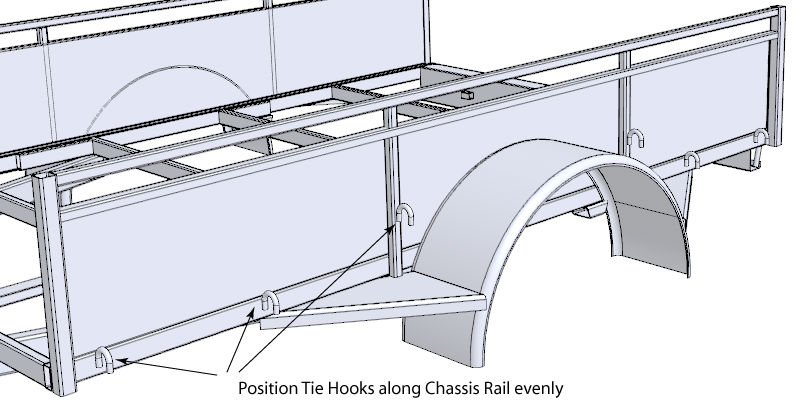

TIE HOOKS

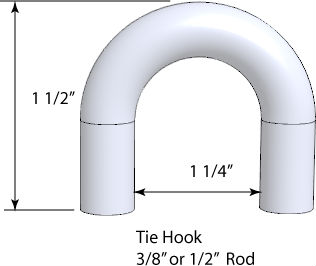

You can fit as many tie hooks to your trailer as you like and some say the more the merrier. Practically you only require four to six tie hooks on each side, and as long as they are strong and can accommodate good sized rope or tie down hooks, there is little else you need.

Tie hooks can be made by rolling a piece of rod around a former in a vice and cutting to size. The easiest tie hooks are made from chopping off the end of chain links.

To prevent your rope chaffing, make sure all surfaces and edges of the tie hooks are smooth.

Weld the tie hooks with good strong welds to the chassis rail and the center uprights.