5' X 8' SINGLE AXLE TRAILER: LIGHTS

Note - Before doing any cable fitting, it is advisable that the trailer is fully prepared and painted or galvanized and at the bare minimum, has a primer coat applied.

Running the light cable

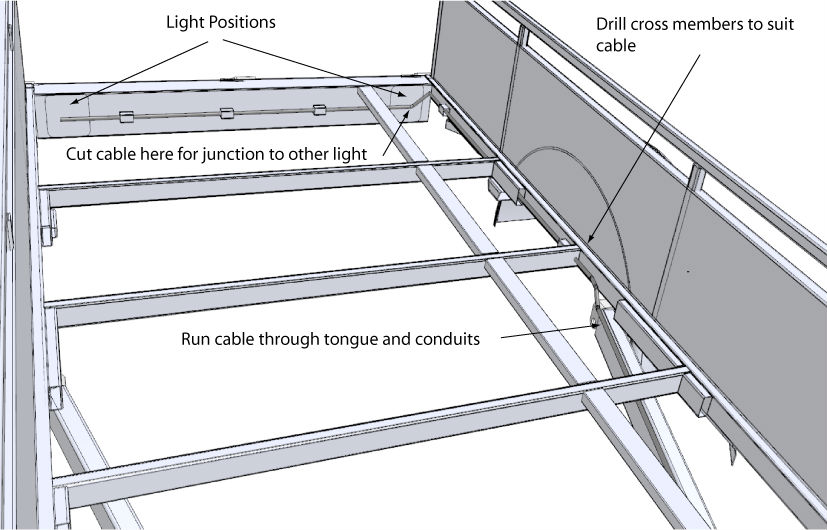

From the front of the trailer, slide a semi-rigid section of mild steel "pull" wire down the tongue until it comes out at the spring end. Tape the trailer 4 core cable (6 or 7 core if you are fitting electric brakes) to the end of the "pull" wire and pull from the spring hanger end until the cable comes through.

Gently pull the cable through until you have a good length that will reach along the length of the trailer and across the rear light channel. Allow another foot or so extra cable to play with.

Allow another 2 foot extra at the coupling end of the tongue for wiring into your plug.

Drill through any cross members not already drilled to allow the cable to be threaded through. Thread the cable from the spring hanger end of the tongue, through the conduits and cross members until you reach the position of your first light. Add on an extra 6" of cable and cut.

Thread the left over cable through the conduits along the light channel to the second light.

Fitting Lights

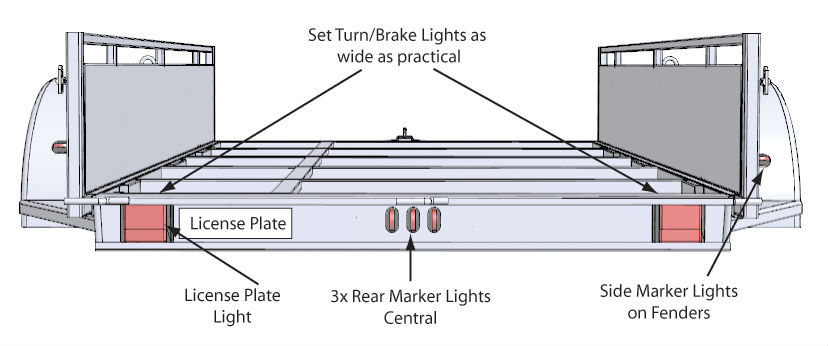

Make sure that your license plate light is in the correct position and that the light will shine on the plate. Keep your Turn/Brake lights as wide as possible in the light channel, but do not place lights directly behind the rod bracing. Find the center of the light light channel for mounting the 3 Marker Lights.

Mark out your light position on the light channel and drill the mounting and cable holes as per your lights instructions or template.

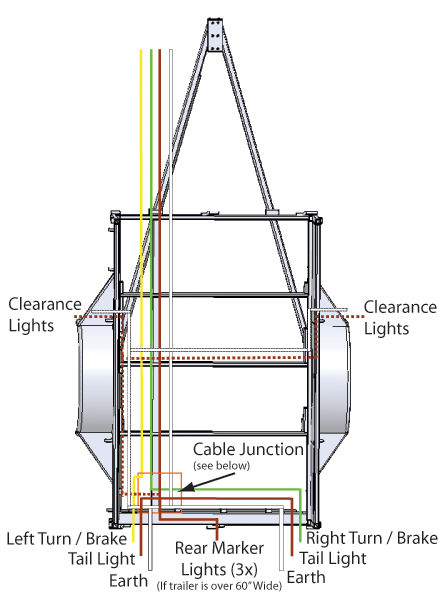

It is normal to run the earth cable directly to the trailer chassis (ground) but I prefer to run an earth to each light to ensure the best grounding.

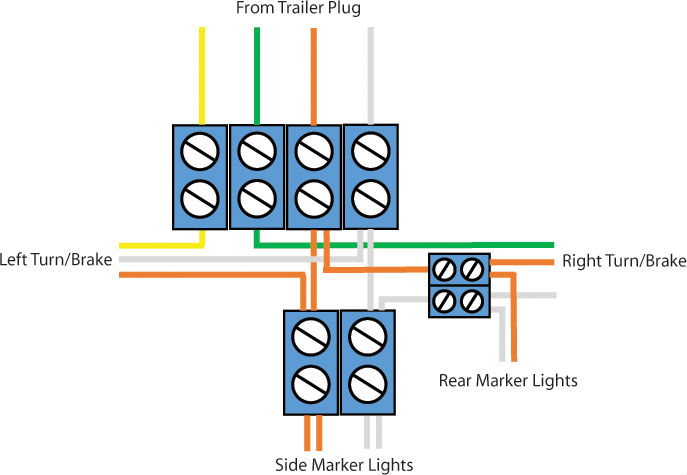

There are a couple of ways of joining the wire together behind the left hand light. Using a strip connector inside a sealed junction box is one of the best ways of keeping the join secure and weather tight and also gives the option of easily changing lights should they get damaged, etc.

There are a couple of ways of joining the wire together behind the left hand light. Using a strip connector inside a sealed junction box is one of the best ways of keeping the join secure and weather tight and also gives the option of easily changing lights should they get damaged, etc.

Other options include soldering the wires together and sealing with insulation tape and a heat shrink tube or using crimp connectors and covering again with heat shrink tube. These options take less time to do than the first option, but will cause a bit of a headache when maintenance needs to be done at a later date.

If you go down the junction box route, secure the box to the chassis rail directly behind the light channel.

SIDE CLEARANCE LIGHTS

For side clearance lights, an additional two lengths of 2 core cable need to be run from the junction box, up through the conduit to the spring hanger. Take one cable under the chassis rail and behind the front of the fender. "P" clip (see photo) the cable in appropriately hidden positions to prevent the cable from being snagged by either the tire or debris flung up from the road. For the other cable you need to "P" clip one cable along the cross member to the right hand spring hanger and again take under the chassis rail up to the light position. Drill the appropriate holes for mounting the light and for the cable to pass through the fender.

For side clearance lights, an additional two lengths of 2 core cable need to be run from the junction box, up through the conduit to the spring hanger. Take one cable under the chassis rail and behind the front of the fender. "P" clip (see photo) the cable in appropriately hidden positions to prevent the cable from being snagged by either the tire or debris flung up from the road. For the other cable you need to "P" clip one cable along the cross member to the right hand spring hanger and again take under the chassis rail up to the light position. Drill the appropriate holes for mounting the light and for the cable to pass through the fender.

Crimp connectors are the most convenient method for joining the wires to sealed lights with attached wiring.

PLUG

Pass the plug end cable through the cable hole drilled in the top or side of the tongue and slide a suitable sized rubber grommet over the cable to prevent any chafing of the cable where it passes through the tongue.

Trim the length of cable so that the cable can move with the trailer behind the tow vehicle without being stretched or kinked, but not too long that it will dangle too close to the ground.

Slide any plug sleeve or nut - that came with the plug - over the cable, then strip each end of the

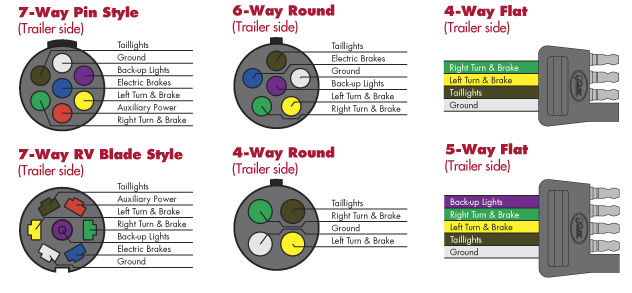

plug wires leaving approximately 3/8" bare wire, fold the bare cable in half and enter them into the plug connector in the correct sequence as per the chart above. Tighten the screws snugly but do not over-tighten. Screw the cable clamp down to prevent the cable from pulling out and fit any sleeves, nuts or covers that came with the plug.

If possible, check all your lights by hooking the trailer plug up to your tow vehicle. If you don't have a mate to help you check your brake lights, grab a mirror and position it behind the trailer where you can see it from the tow vehicle.