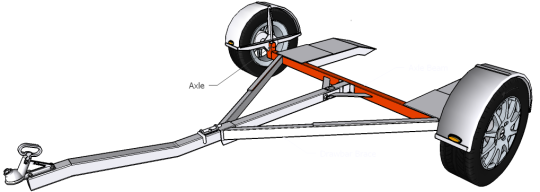

Tow Dolly

Axle Setup

Setting up the axle takes a little bit of working out to ensure there is adequate clearance between the wheel/guard and the pivoting top deck/towed vehicle when rotating.

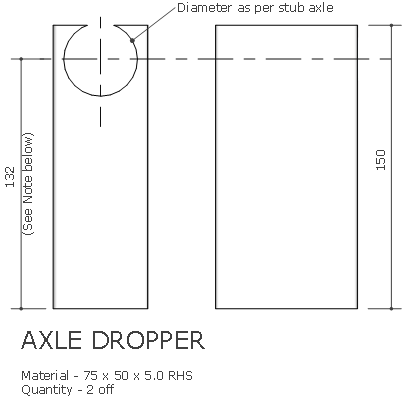

The details below are for a standard 39mm diameter stub axle (1500kg) fitting, which in the majority of towing circumstances is more than adequate.

Where a larger diameter stub axle is used, mount the stub axle in an overlay arrangement. Increase the axle dropper SHS thickness from 5mm to 6mm and scallop out the SHS sides to locate the stub axle and increase weld strength.

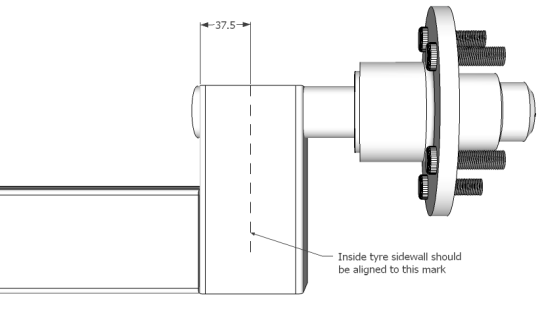

To find the correct stub axle position within the axle dropper, first dry mount the hub and wheel to the stub axle. Find the centre of the axle dropper and mark.

Slide the axle dropper over the stub axle and align the tyre using a straight edge, until the inside side wall of the tyre is level with the mark on the axle dropper.

Mark or measure the stub axle position.

It may be necessary to trim the end of the stub axle so that a maximum of 10mm is protruding from the axle dropper.

Setting up the stub axle should be undertaken as per the instructions on the "Building a Trailer Axle - Dropper Plates" page.

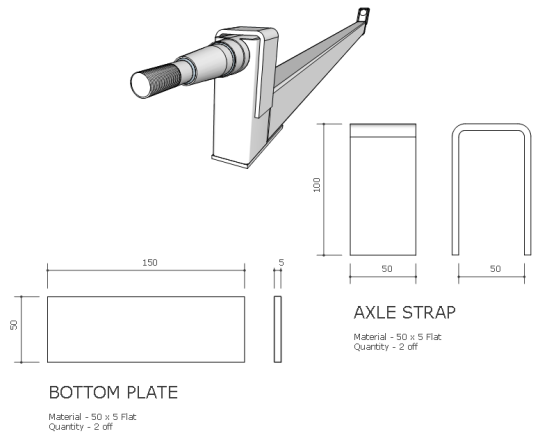

Once the stub axle has been fully welded in position, fit the axle strap and bottom plate and stitch weld to the axle.